GRP gratings

GRP gratings

The advantages of Glass fibre Reinforced Plastic

The advantages of Glass fibre Reinforced Plastic

Fiberstruct GRP has a high strength-to-weight ratio compared to traditional materials such as metal, concrete, and wood. GRP gratings can even be strong enough to carry vehicle loads while weighing up to 70% less than steel gratings.

GRP is corrosion-resistant and requires less maintenance than steel. The durability and corrosion resistance of Fiberstruct GRP gratings and other GRP products reduce or eliminate the need for major maintenance such as sandblasting, scraping, and painting.

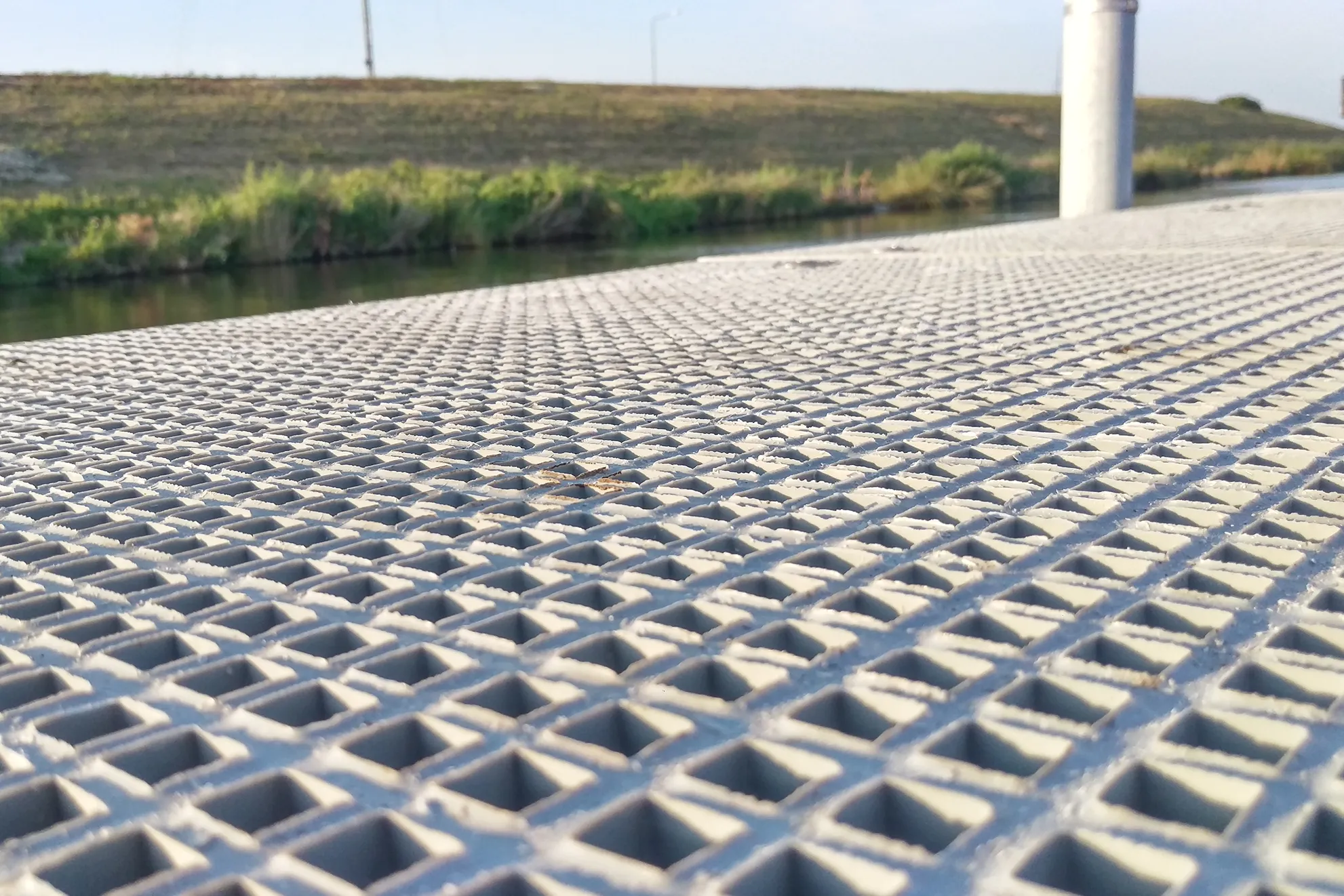

Choosing GRP gratings is choosing safety. Fiberstruct’s GRP gratings and stairs provide a superior, slip-resistant surface in wet and oily environments. Fiberstruct GRP products are also non-conductive and have a higher friction factor than steel. This reduces the risk of electric shock and slip injuries. GRP is the clear choice for safer structural products.

Weather-resistant, anti-slip, and extremely versatile

Weather-resistant, anti-slip, and extremely versatile

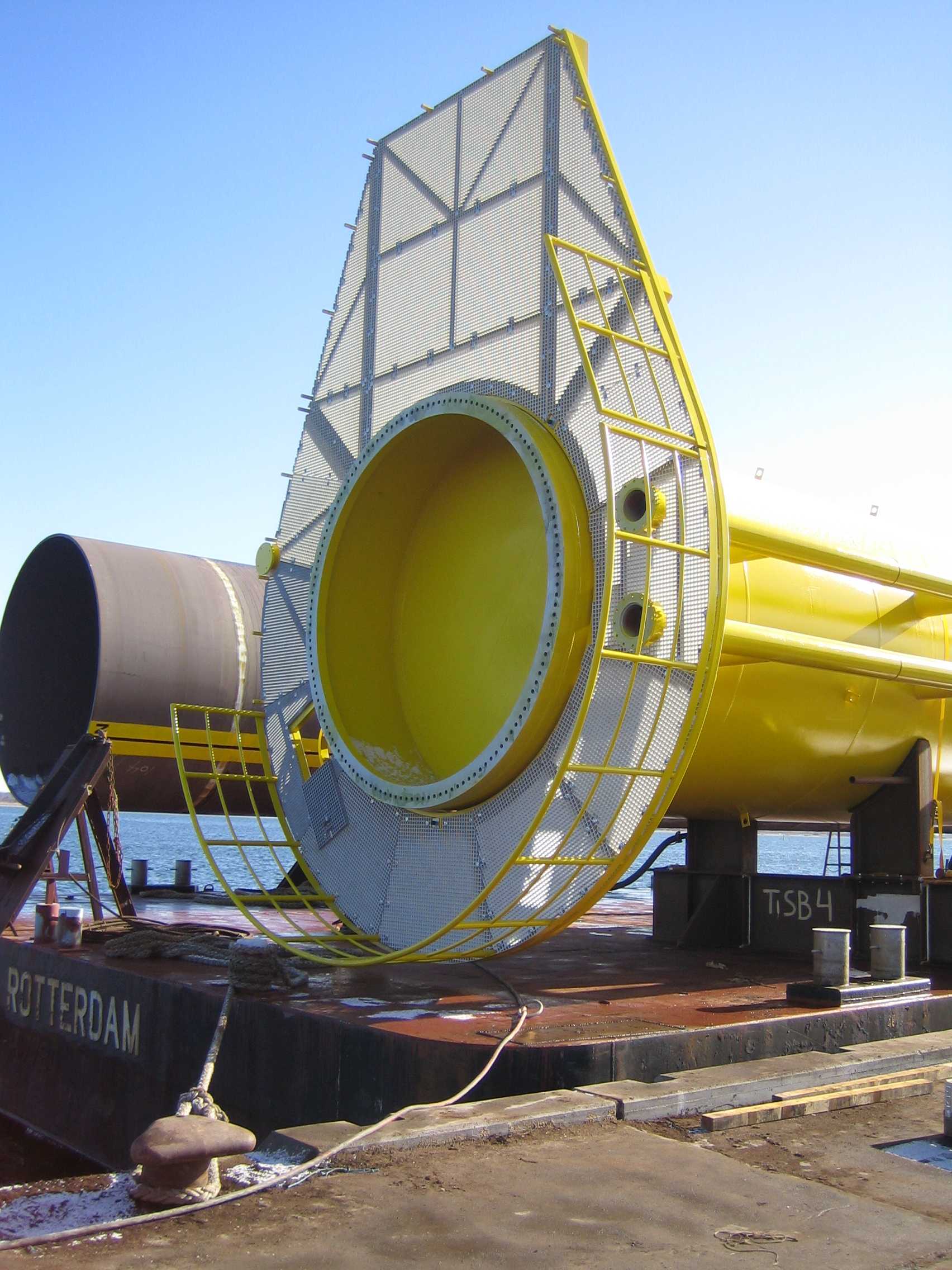

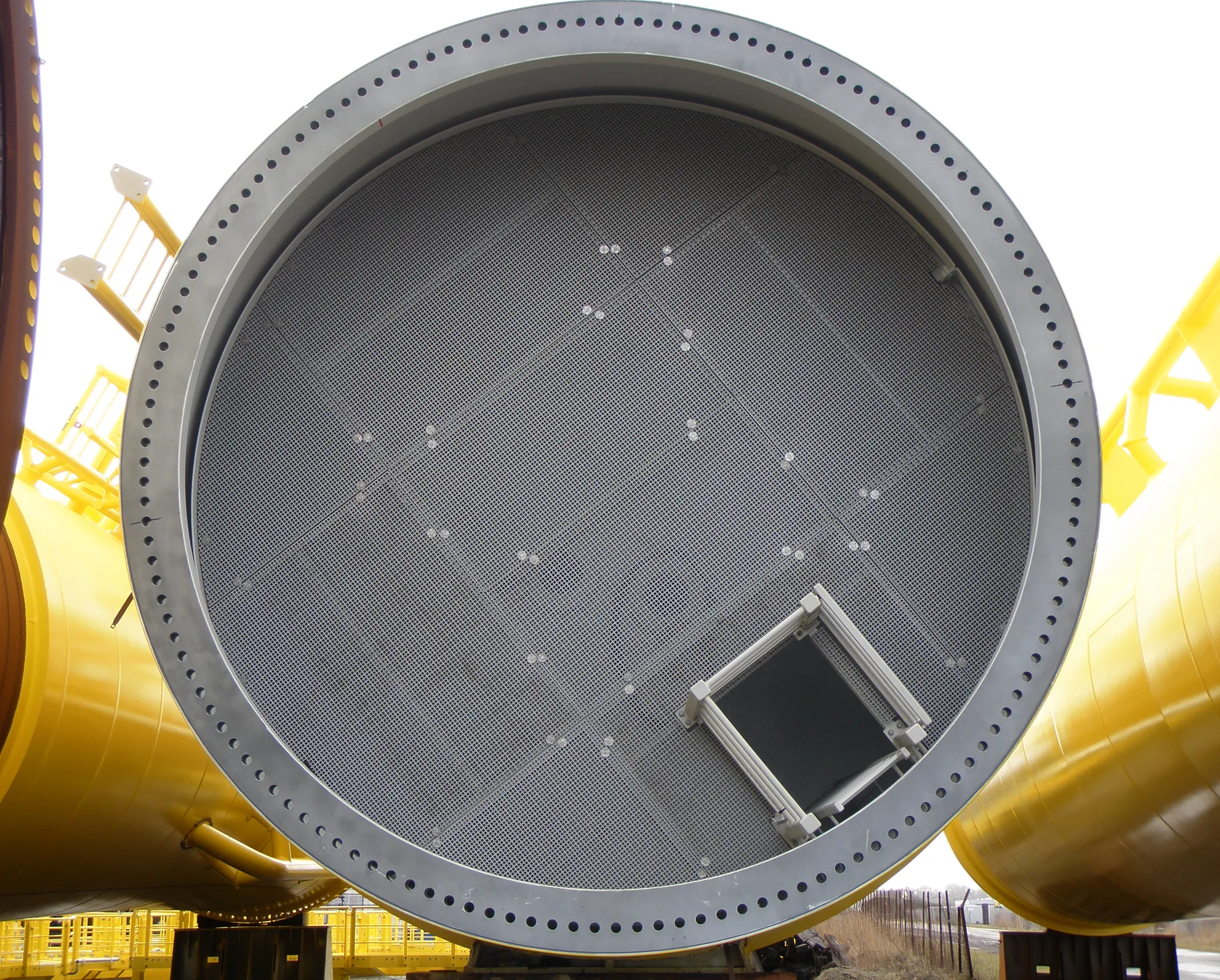

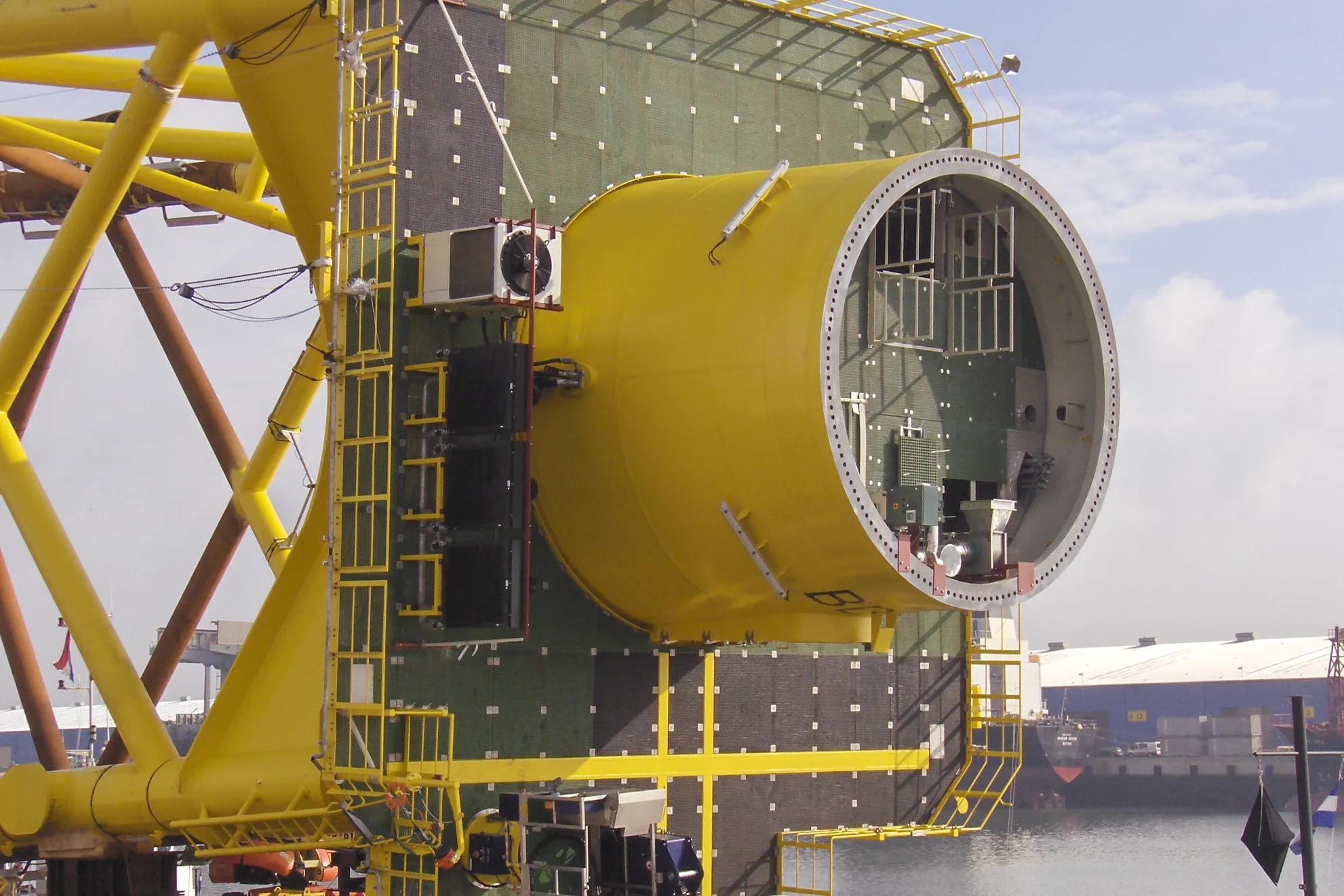

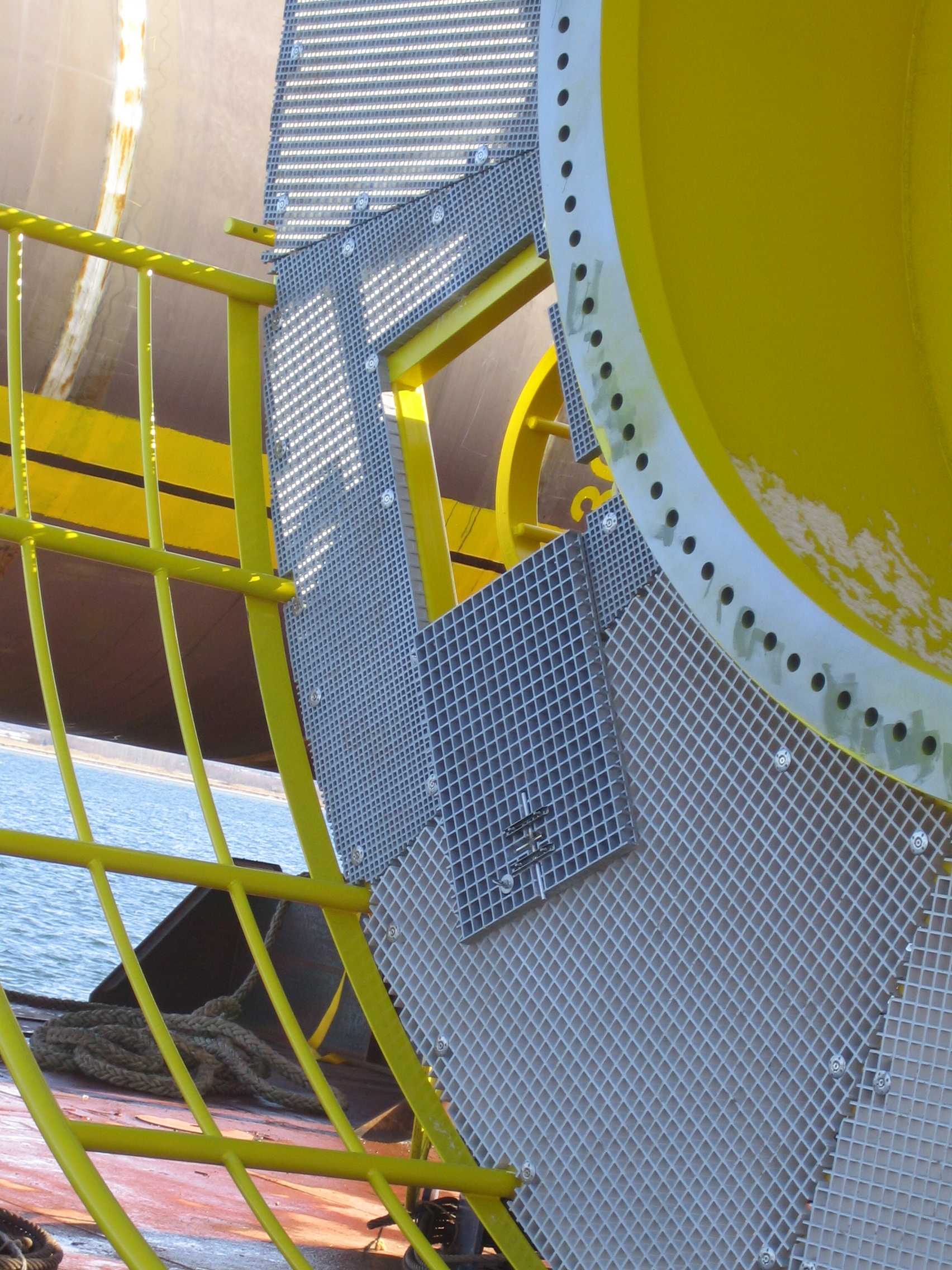

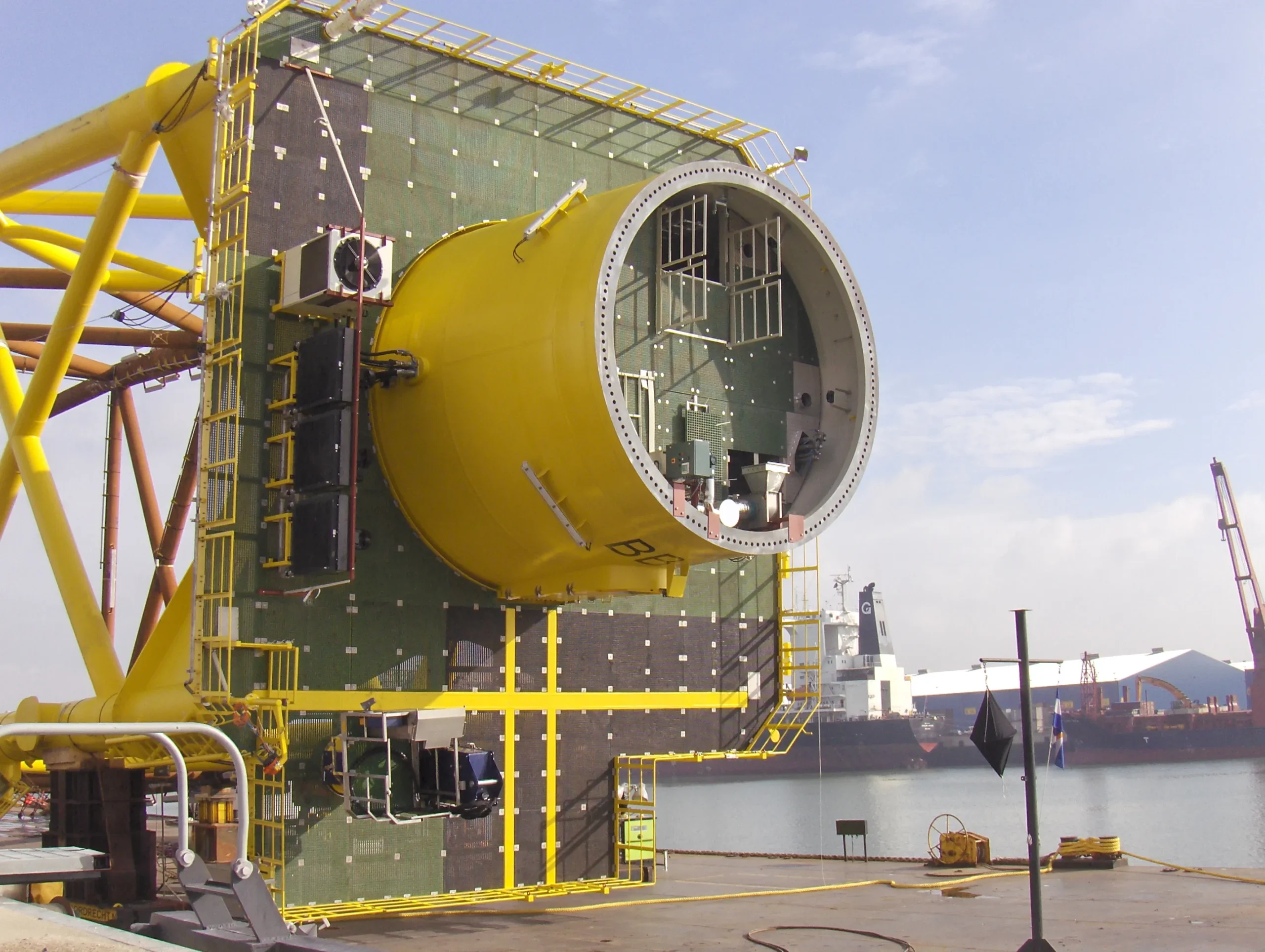

Fiberstruct creates high-quality glass fibre reinforced plastic (GRP) walkway gratings for a variety of industries. Thanks to its wear-resistant and non-corrosive properties, GRP is perfectly suited for applications in specific fields, such as shipbuilding, shipping companies, the chemical industry, and offshore.

We offer standard grating types and panels in virtually any size and RAL colour. Moreover, we specialise in the mounting of GRP gratings and our engineering department creates customised designs.

Standard dimensions

Standard dimensions

As a manufacturer of GRP gratings, we stock many standard sizes, with quick and easy delivery.

For advice on which type of grating is suitable for your application, don’t hesitate to contact us. If you prefer to find the right type yourself, download our overview of standard gratings below.

Customisation

Customisation

Fiberstruct stands out in its many customisation options. We realise customised projects on the basis of supplied drawings. But we do more: Upon request, we can develop a comprehensive grating plan to meet specific needs. After consultation, the GRP gratings or panels can be cut to size and delivered with open and closed meshes.

Open / closed meshes

Open / closed meshes

Choose from gratings with open or closed meshes, depending on your requirements. As a standard, our GRP gratings are manufactured with open meshes, which are excellent for various applications such as walkways, landings, platforms, and stairs. For extra protection, we also offer gratings with closed meshes, making them perfect for situations where extra safety is required.

Open / closed top layer (HLU)

Open / closed top layer (HLU)

Choose from gratings with an open or closed top, depending on your requirements. Our closed GRP gratings are produced by using an open GRP grating combined with dense laminated fibreboard. This fibreboard varies in thickness from 3-5 mm and has a standard anti-slip layer. This type of GRP panel is extremely suitable for a variety of different applications, such as walkways, landings, platforms, bridge decks.

Resin type

Resin type

Orthophthalic polyester (ORTHO)

This type of resin offers excellent resistance to atmospheric corrosion, making it ideal for outdoor use, such as in public areas, bridges, and platforms. Intergrate® ORTHO GRP gratings are produced with a high-quality patented orthophthalic polyester resin combined with a continuous woven glass fibre pattern.

Isophthalic polyester (ISO)

Isophthalic polyester resins are particularly suitable for applications in corrosive and chemical environments, such as industrial plants, water treatment plants, and chemical factories. Intergrate® ISO GRP gratings are produced with a high-quality patented isophthalic polyester resin, combined with a continuous woven glass fibre pattern.

Vinylester (VE)

Vinylester resins are known for their excellent chemical resistance to acids, salts, and other corrosive substances. They are often used in challenging, heavily corrosive environments. Our Intergrate® VE GRP gratings are produced with a high-quality patented vinylester resin combined with a continuous woven glass fibre pattern

Phenol (PH)

Intergrate® PH GRP gratings are produced with a high-quality patented phenolic resin combined with a continuous woven glass fibre pattern. Phenolic resins offer optimum chemical resistance, excellent fire resistance, and minimise smoke development when exposed to fire.

Projects

Projects

Get in touch with Fiberstruct

Get in touch with Fiberstruct