GRP products

for marinas

GRP products

for marinas

We offer the maritime sector unique opportunities in terms of durability and performance with our GRP products. In the recreational industry, Glass fibre Reinforced Plastic walkway gratings and products are also a good and cost-effective solution. Fiberstruct has extensive experience in using GRP gratings at marinas as a very durable, attractive, and maintenance-free solution for refurbishing or replacing/renovating their jetties.

Fiberstruct has an extensive product portfolio that perfectly meets the demand for low-maintenance, corrosion-resistant solutions for marinas. Discover how our advanced materials improve the maritime sector.

Adapted surface for comfort

Adapted surface for comfort

Unlike industrial applications, comfort is an additional requirement for GRP walkway gratings at marinas. After all, people often walk barefoot on jetties, so it is nice if they can do so comfortably.

Especially for use in marinas and water sports clubs, Fiberstruct offers GRP walkway gratings with a mildly gritted surface, which means a surface with a smaller and finer grain. This makes it excellent to walk on with bare feet without pain.

European production

European production

Fiberstruct is a leading European manufacturer of GRP products for the maritime industry. With an experienced team of engineers in the Netherlands and a state-of-the-art production facility in Slovakia, we can offer in-house, custom-made solutions that meet the specific requirements of each project.

From concept to production and installation, Fiberstruct guarantees high-quality products and excellent service.

In-house engineering

In-house engineering

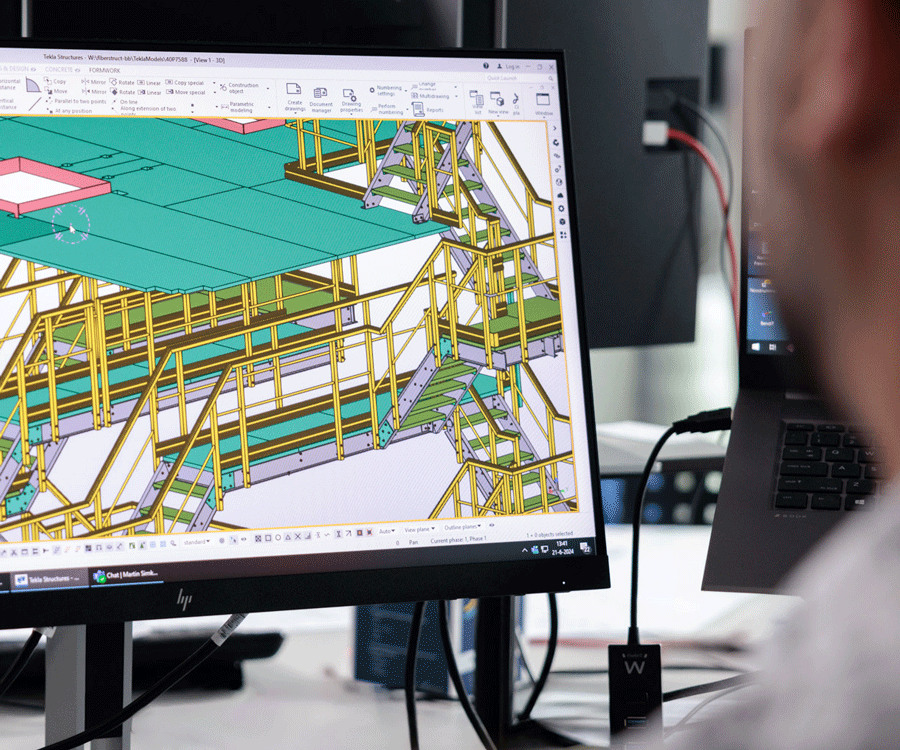

In addition to delivering gratings, we can provide engineering and static calculations to ensure the right choice of gratings for any situation, considering the loads and (steel) drawings.

We also optimize the layout of the gratings using 2D and 3D engineering software to minimize cutting waste and ensure the best fixation method. By engineering and marking the gratings, we save costs by reducing installation time.

Why choose GRP over steel

Why choose GRP over steel

Fiberstruct is your partner for glass fibre reinforced plastic gratings, handrails, guardrails, ladders, and other structural product needs. Our professional engineering and production team will assist you from start to finish to find the right solution to meet your needs in terms of sustainability, safety, and cost. The many advantages include:

GRP is corrosion-resistant and requires less maintenance than steel

The durability and corrosion resistance of Fiberstruct GRP gratings and other GRP products reduce or eliminate the need for major maintenance such as sandblasting, scraping, and painting. In fact, most Fiberstruct products are easy to clean with a pressure washer.

Non-conductive

Your team’s safety is your top priority. Fiberstruct GRP products are non-conductive and have a higher friction factor than steel, reducing the risk of electric shock and slip injuries. GRP is the clear choice for safer structural products.

GRP is up to 70% lighter than steel with a high strength-to-weight ratio

Fiberstruct GRP has a high strength-to-weight ratio compared to traditional materials such as metal, concrete, and wood. GRP gratings can even be strong enough to carry vehicle loads while weighing less than steel gratings.

Corrosion-resistant

Fiberstruct glass fibre reinforced plastic (GRP) products are known for their ability to provide corrosion resistance in the most demanding environments, as well as exposure to chemicals. Unlike metal and wood, GRP products will not rust or corrode and will retain structural integrity over time.

Fiberstruct offers the largest selection of resin compositions for products, each specifically developed to meet specific environmental and performance requirements. Check out Fiberstruct’s Chemical Resistance Guide to help you choose the best Fiberstruct resin for your application environment.

Anti-slip / Slip-resistant

Fiberstruct’s GRP gratings and stairs provide a superior, slip-resistant surface in wet and oily environments. Steel becomes slippery when oily or wet, but Fiberstruct gratings have a higher friction factor and remain safe even when wet. Fiberstruct’s slip-resistant products increase worker safety, which will lead to fewer workplace accidents and a reduction in injury-related costs.

Marina reference projects

Marina reference projects

Other markets

Other markets

Contact us for more information!

Contact us for more information!